- Stories

- Community Stories

- State Highway 25 Roading updates, news and announcements

State Highway 25 Roading updates, news and announcements

Featured

This article shares a summary of updates provided by the New Zealand Transport Agency Waka Kotahi on State Highway 25 and 25A roads on the Coromandel Peninsula.

(Image Credit: NZTA Waka Kotahi. An artist's impression of the new 2-lane Pepe Stream Bridge project looking south from the Tairua town centre).

Help us get the word out!

If you like this article, please share it!

The following information is provided via New Zealand Transport Agency Waka Kotahi (NZTA) and Thames Coromandel District Council sources. Information may be subject to change, and the most up to date road status information can be viewed on the NZTA Waka Kotahi website.

NZ Transport Agenc Journey Planner Link

For traffic and travel information and to plan your journey to find travel times, incident and roadworks information, and regional traffic updates go to the NZTA Journey Planner.

Tairua two lane Pepe Stream Bridge plans - NZTA update 28 January 2026

Planning for construction of the replacement Pepe Stream Bridge is ramping up and we will be back in Tairua for another public information day on Thursday 26 February.

This will be at the community hall, and people can call in any time between 2pm and 6pm.

Subject to consents being granted by the end of April, we expect to bring the start of construction from spring to July.

Fulton Hogan was awarded the contract in November last year and is working with WSP to finalise consents and design so they can start mid-year on the new 2-lane bridge.

NZTA state that building a new bridge in a tight urban and coastal environment, while maintaining access for vehicles and walking and cycling will be challenging. Fulton Hogan’s plans and methodology will be a key part of the information day.

Initially a temporary pedestrian bridge will be built upstream of the current vehicle bridge. Services will be relocated on to this bridge, and then the existing pedestrian bridge will be removed.

Fulton Hogan will build one lane of new bridge, and shared path, on the east (seaward) side. Traffic will then be run over the new lane while the old bridge is dismantled, creating room to build the other half of the new bridge and a footpath.

Key dates ahead:

• Public information day 26 February

• Consent conditions lodged by end of February

• Consents granted by end of April

• Detailed design finalised by end of June

• Early works (services etc) May-July

• Construction scheduled to start July

• Bridge completed by December 2027.

SH25 Temporary Speed Limits to Change

19 August 2024

Temporary speed limits on State Highway 25 (SH25) around the Coromandel Peninsula will soon be reverted to their previous levels. These temporary speed reductions were implemented as an emergency measure following the 2023 weather events and the closure of State Highway 25A, which led to altered traffic patterns and increased volumes in some areas.

According to NZ Transport Agency Waka Kotahi (NZTA), temporary speed limits can only remain in effect for a maximum of 12 months without renewal. Since the emergency situation has passed and SH25A has reopened, the temporary speed limits will be removed by early October, with permanent speed limits reinstated.

While NZTA recognizes that there is community support for retaining reduced speeds in some areas, changing a speed limit is a legal process that involves multiple steps. In June and July 2024, the Ministry of Transport conducted a consultation on a new Land Transport Rule for setting speed limits, and this new rule is expected to be finalized in the coming months.

Once the new speed rule is finalized, NZTA will evaluate how it applies and whether any of the temporary SH25 speed limits should be made permanent to meet community needs.

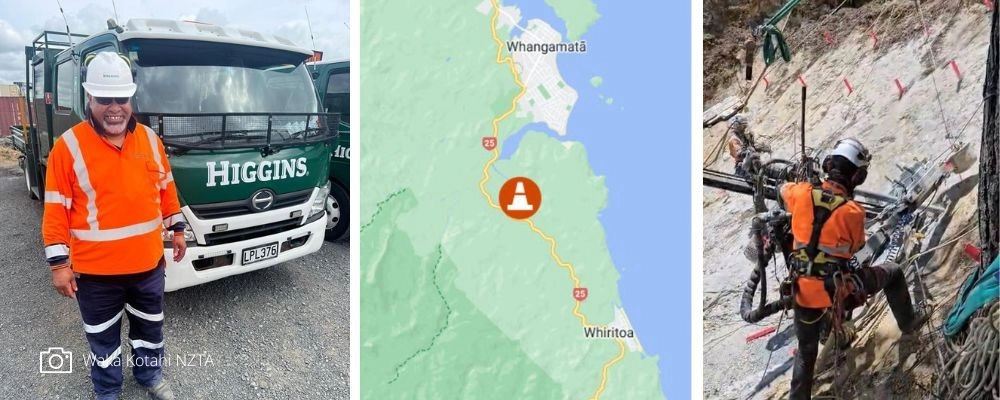

SH25 Recovery Programme Ramps Up After Winter

As spring and summer approach, work to repair the damage to SH25 caused by the extreme weather events of 2023 will intensify.

Currently, repairs are underway between Opoutere and Hikuai to address two underslips in close proximity to each other. In September, work will begin on Pumpkin Hill near Tairua and north of Wharekaho, with additional projects starting in October.

Each of these projects is expected to take around two months to complete, weather permitting. Stop/go traffic management and temporary speed restrictions will be in place for the duration of the works.

The recovery programme is being carried out with careful consideration to balance the speed of delivery with minimizing disruption to road users, especially during the busy summer holiday period.

New Two-Lane Pepe Stream Bridge Announced by Transport Minister

Update 22 July 2024

Transport Minister Simeon Brown has announced that the one-lane Pepe Stream bridge on State Highway 25 in Tairua will be replaced with a modern two-lane bridge. This announcement was made on the government Beehive website following Minister Brown's visit to the Coromandel this morning. The construction of the new bridge is expected to be completed within three years and is part of a program to replace nine ageing bridges across the country.

“This is great news, the bridge has been a bottleneck for summer visitors and locals at peak periods for many years now. At the height of summer, we’ve had traffic backed up for several hours in each direction. There are other one-lane bridges on either side of Tairua that contribute to the congestion, but this particular bridge, right in the middle of Tairua, has been a problem for years, so we’re really looking forward to its replacement.”

Len Salt - Thames Coromandel District Council Mayor

Tairua-Pāuanui Community Board Chair Warwick Brooks also welcomed the announcement. “The old bridge is no longer fit-for-purpose. Tairua is growing, and having a one-lane bridge operating at one end of our commercial precinct is neither suitable for our town nor particularly safe. I’m really happy to hear about the government’s announcement.”

The Pepe Stream bridge, built in 1942, is now at the end of its lifespan. Waka Kotahi NZ Transport Agency regularly inspects and maintains the bridge, ensuring it remains safe. Several years ago, NZTA began a business case to explore replacement options.

Work to finish on Ruamahunga Slip site

Update 12 June 2024

Recovery efforts at the significant slip-site in Ruamahunga are approaching completion. While some minor finishing touches remain, the primary tasks of clearing debris, installing soil nails, and applying netting are now largely finished.

On Thursday, June 13, a helicopter will be on-site to remove equipment and supplies from the top of the slip-site. To ensure safe helicopter operations, this will necessitate a series of brief road closures.

Contractors are also actively clearing debris from a new slip, which includes large tree roots, after a significant tree fell 30 metres down the bank, blocking the road for most of last Monday. The existing stop/go traffic management has been extended to cover this new slip location.

The team is working diligently and may require additional short road closures to ensure the safe completion of these tasks. Anticipated wet weather later this week could potentially impact work progress.

Once the work at both sites is completed, the road, which has been operating as a single lane since October 2023, will be restored to two lanes. This restoration is expected to occur within the next two weeks. However, further temporary lane closures may be necessary occasionally to accommodate additional work in this area.

Since the major repair work began in October last year, contractors have removed approximately 2,500 tonnes of material from the slope, predominantly by hand. They have installed over 500 soil nails and approximately 1,500 square metres of mesh.

Given the steepness of the slip-face, helicopters have been regularly utilised to clear vegetation and deliver supplies and equipment to the top of the worksite.

Other works progress

Significant strides have been made in the recovery efforts on State Highway 25, with three more slip sites successfully completed over the past month. The repairs to the underslips at Te Kouma, Pumpkin Hill, and Whiritoa Hill are now finished, and the highway has been restored to its full width at these locations.

On State Highway 2 at Victoria Battery in the Karangahake Gorge, work to construct a retaining wall is progressing well. The highway is expected to reopen to two lanes by Matariki weekend.

Before the end of the month, work is anticipated to commence on constructing a sea wall along the highway at Kuranui, north of Thames. Additionally, drainage repair and clearance efforts continue between Waihi and Whiritoa.

Looking ahead, further work to address highway damage is planned to begin in August. These efforts will focus on areas near Kuaotunu, Pumpkin Hill, and between Hikuai and Opoutere.

Overnight Closures on SH25 at Hikuai Bridge

State Highway 25, south of Tairua, is set for overnight closures spanning 5 nights from Sunday, May 19, between 8:00 pm and 6:00 am. These closures are essential to facilitate maintenance and repairs on the single lane Hikuai Stream bridge.

Affected road users will be required to detour via SH25, looping through Coromandel township. While acknowledging the inconvenience posed by this lengthy detour, NZTA Waka Kotahi emphasises the importance of this maintenance work.

The scope of work encompasses digging out and replacing capping beams, critical components spanning the full width of the road at each end of the bridge. To ensure safety, steel plates will be placed over these excavations, with a temporary speed restriction enforced during the day to facilitate safe passage of traffic.

Additional maintenance tasks planned during the closure include resurfacing the eastern approach to the bridge and repairs to the bridge deck. It's worth noting that the execution of this work is dependant on weather conditions, with updates provided promptly should there be any changes to the scheduled dates.

While exploring options to minimise disruption, including opening the road for short periods each night for convoys of traffic, it was determined that such a measure could impede work progress, necessitating additional night closures and prolonging overall disruption.

Collaboration with emergency services is underway to ensure they can be accommodated if required.

SH25 Ruamahunga Bay Recovery Works Progress

Progress is underway on the stabilisation of two out of the three slip faces on SH25 at Ruamahunga Bay, with work anticipated to continue through July. Helicopters remain instrumental in delivering equipment and supplies to the slope's summit, with the next delivery scheduled for Tuesday, May 14. This operation necessitates brief road closures across midday to ensure safe helicopter operations.

Elsewhere along the SH25 loop, work has concluded at underslips at Wharekaho and Kereta, restoring the road to its full two-lane width. Initial repair works have commenced at Te Kouma and Pumpkin Hill, with stop/go traffic management in place.

Repair efforts are ongoing at Whiritoa Hill and secondary sites at Te Kouma and Pumpkin Hill, with similar traffic management measures in effect. Concurrently, repair works are also underway on SH2 in the Karangahake Gorge and SH27 at Kaihere.

With the onset of the wetter winter months, focus will shift to drainage and culvert repairs at various locations around the peninsula. Work involving significant earthworks will pause during this period, resuming with earnest in the ensuing spring and summer months.

Roading Update

Update for 22 March 2024

The Taparahi Bridge on State Highway 25A will be down to one lane on Monday and Tuesday this week. There will be stop/go traffic management in place to allow contractors to finish some critical work at the site.

The Ruamahunga slip site stabilisation continues. The next closure is scheduled for April 3, so a helicopter can deliver supplies to the site. The road may be closed for up to 20 minutes at a time between 12 noon and 2pm.

Recovery work is also underway at Kereta, Te Kouma and Wharekaho.

Overnight Closure confirmed

Update for 6 March 2024

On Wednesday, March 6, Waka Kotahi has confirmed an overnight closure of SH25A to facilitate final works at the new bridge located at Taparahi. The closure is to install a new rubber seal into one of the bridge joints, spanning the entire width of the road. Additionally, grates will be installed on the side drains along the eastern approach road.

To minimise disruption to road users, the work is scheduled overnight, with the road closing from 9:30 pm on Wednesday, March 6, until 5:00 am on Thursday, March 7. Detours will be in place via SH25 along the Thames coast and Coromandel township or via SH26/SH2/SH25 through the Karangahake Gorge, Waihi, and Whangamata. While local traffic access along SH25A will be maintained up to the bridge from both the east and west, crossing the bridge itself will not be possible during the closure.

Coromandel State Highway Recovery Programme

The recovery programme to repair damage inflicted by last summer's extreme weather events continues at various sites across Coromandel's state highway network. While the slip that closed SH25A stood as the most significant, there were an additional 50 major slip sites and further damage caused by surface flooding at multiple locations across the wider network.

The work is expected to extend throughout 2024, with the focus on repairing and fortifying vulnerable sections. Delays for road users are anticipated, and Waka Kotahi will closely monitor the impacts to strike the right balance between speed of delivery and minimising disruption to road users.

Overnight Road Closure Planned for SH25A

Early March will see an overnight closure of SH25A, Kopu -Hikuai at the Taparahi Bridge for one night. The exact date is not yet known. It is expected that the road will be closed from 11pm to 4am for the one night. The time will be used to replace a rubber seal into one of the bridge joints and to install grates on drainage channels.

NZTA will provide more information as soon as the date is confirmed.

Delays at Ruamahunga

Good progress is being made at stabilising the SH25 Ruamahunga slip. Deliveries of supplies need to be made to the site by helicopter and these will be made every second Friday, commencing Friday 23rd February. This will mean that the road will close for periods of up to 20 minutes at a time between 12 noon and 2pm on these days.

Completing the Job on SH25A

Update for 7 February 2024

The project team has returned to SH25A Taparahi to wrap up the remaining works. Tasks include the removal of temporary bracing under the bridge deck, finalizing drainage infrastructure, and conducting earthworks. As part of this process, they're also testing soil nails and gradually dismantling site offices, fences, and gates. Once these tasks are complete, the material storage area and helipad will be reinstated. Please note that a temporary speed limit is in place to ensure the safety of the team.

Recovery Works Resume Across Coromandel Highways

From mid-February, efforts to repair the damage caused by last summer's extreme weather across Coromandel's state highway network will intensify. With stop/go traffic management in place at up to six locations around the peninsula initially, and up to 10 locations by mid-March, delays are expected. Road users are advised to plan ahead and allow extra travel time. Waka Kotahi thank everyone for their patience as they work to ensure the resilience of Coromandel's highways.

Wharekaho under slip & local update

Work to repair an underslip at Wharekaho has commenced off-road to minimize traffic disruptions. Starting from February 12th, the side barrier will be shifted to reduce the road to a single lane, facilitating work on two fronts. Additionally, repairs are set to begin at Te Kouma Hill, Kereta Hill, and Pumpkin Hill, with each location reduced to a single lane with stop/go traffic management in place.

SH25 Whiritoa to Whangamata - Planned Works Update

From Wednesday, February 7th, road resurfacing works will prompt daily periodic closures on SH25 between Whangamata and Whiritoa, just south of Parakiwai Quarry Road. These closures, anticipated to last around two weeks (weather permitting), will see the road shut for up to 30 minutes at a time between 7:00 am and 6:00 pm. Temporary speed restrictions will be enforced once the road reopens to facilitate smooth traffic flow.

Ruamahunga – Rolling Closures on 9 February 2024

State Highway 25 will undergo brief closures on Friday, February 9th, to facilitate safe helicopter operations over the road. The closures, lasting up to 20 minutes at a time, will enable the helicopter to transport equipment and materials to the top of the slope and remove cleared trees. Following each closure, the road will promptly reopen to allow traffic to clear before the next closure. Please note that this work is weather-dependent, and any unsuitable weather conditions will result in postponement. This ongoing work is anticipated to continue until mid-2024.

Respect for Road workers

Road workers are hard at work making Coromandel roads better and safer this summer. With maintenance activities such as repairing potholes and resealing in full swing, it's crucial for drivers to be patient, respectful, and drive safely through work sites. Adhering to speed limits, following signage, and obeying instructions is paramount. For updates on work impacting state highways, visit journeys.nzta.govt.nz/traffic.

SH25A Open!

State Highway 25A is officially open for travel! This morning, December 20th 2023, marked the reopening of the fully restored road and the brand-new bridge, a significant milestone after the slip caused by severe weather earlier this year. Take a look at the new bridge and listen to some involved in the build in this recent video.

Waka Kotahi extend a heartfelt gratitude for the community's patience and unwavering support throughout the past few months. A special commendation goes out to the dedicated workers, both onsite and offsite, who tirelessly contributed to this project—from the grounds in Coromandel to the distant site in Napier, where crucial parts of the bridge were prefabricated. Their remarkable efforts led to reopening the road well ahead of schedule.

Please note that while the area surrounding the new bridge remains an active worksite, Waka Kotahi have implemented reduced speed limits and traffic management for everyone's safety.

For safety reasons, it's crucial not to halt or sightsee on the bridge or its immediate vicinity. Given the anticipated heavy traffic during the holidays, your cooperation is pivotal in ensuring a smooth flow of vehicles through the site. Kindly refrain from stopping, adhere to speed limits, and drive safely when navigating this area.

The team are immensely grateful for the overwhelming support and encouraging feedback received from all. The positivity has been a driving force throughout the journey. And, they wish everyone a joyful and secure holiday season as we traverse the restored road!

The Bridge by numbers...

For those into detail, here’s some numbers about the new bridge:

- 124m long and 15m high 3-span composite design bridge with pre-cast concrete deck

- 100 + people working on and off site

- Estimated cost approximately $43M (under the $50M estimate)

- 491 soil nails in the slip face to treat unstable soil slopes

- Piles bored at least 10m into the rock (for solid rock foundation); deepest pile 41 metres -twice the depth of the other piles (about 22 metres deep)

- Steel beams measuring 18, 29, and 30 metres long fabricated by Eastbridge Ltd in Napier factory

- 138 pre-cast concrete deck panels constructed by Fulton Hogan in Ranui

- 52 pre-cast side barriers fabricated in Tauranga by supplier Preco for the bridge deck

- Around 75 tonnes of cement injected into slip material to retain and stabilise the land

- 100 tonne piling rig

- 2x100 tonnes cranes & a 250T Crane

- Seven excavators, totalling 124T of earthmoving power on site

- 30T and two10T tracked articulated dump trucks

- 19 machines on site including broom sweepers, rollers, and some smaller drilling rigs.

SH25A repair update for 12 December 2023

The final touches are underway as SH25A gears up to welcome traffic next week. Despite some erratic weather, the team has completed critical tasks such as chip sealing, laying the final layer of asphalt, and installing barriers and signage.

This week focuses on essential finishing works, sealing the bridge barriers, refining drainage connections, and ensuring site readiness for post-reopening tasks. Traffic management remains a priority to safeguard incomplete areas and enable safe worker access.

Soil nailing on the slip face is now in its final stages, with grouting and the installation of bearing plates and mesh ongoing.

Planning your First Trip on SH25A? Here’s What You Need to Know

As the road reopens on Wednesday, December 20th, it's crucial to be aware that the area surrounding the new bridge will remain an active worksite. Temporary traffic management and speed restrictions will be in place, including newly sealed areas.

While curiosity about the new bridge and slip site changes is natural, stopping or slowing down for sightseeing poses risks. Keep traffic flowing smoothly and maintain safe speeds.

As the holiday season nears, expect increased traffic. Patience, safe driving practices, and adherence to posted speeds are pivotal to ensuring a smooth flow on SH25A.

Acknowledging Gratitude: Prescott’s Garages’ Kind Gesture

Prescott’s Garages from Hikuai showed appreciation for the team’s efforts by surprising them with pies and drinks last Thursday. The business, like many others, has faced challenges due to the road closure.

The team was thrilled by this heartfelt gesture, expressing gratitude for the continuous support from the local community.

Meet the Team – Nicola Ruffle

Nicola Ruffle, also known as Nikki, has been in Thames since 2018 and serves as the site gatekeeper/security officer.

• Work Experience: With qualifications in Health and Safety and extensive experience in civil roading, truck driving, and security, Nikki's passion lies in ensuring safety.

• Project Insight: Nikki sees the bridge as a vital connector for the Coromandel community, fostering a sense of unity and support.

• Local Connections: With ties to Thames through her partner's heritage, Nikki feels connected to the region.

• Hobbies: Outside work, Nikki enjoys collecting gems, learning tarot card reading, and nurturing her interest in crystal healing, aspiring to open a healing business in the community.

Roading update for 5 December 2023

With each passing week, the completion of the SH25A bridge draws nearer.

Recent progress has seen the team accomplish several significant milestones. The soil nailing, stabilising the slip-face, is now completed, with the team focusing on grouting, mesh installation, and positioning bearing plates on the slip face.

Noteworthy advancements include the completion of the pavement on the western road approach, installation of kerb, channel, and transition side barriers between the road approach and the bridge, and the placement of precast stormwater u-channels on the eastern approach. The hydroseeding of the slope above the southern side of the road has also been executed, enhancing the area's stability.

On the bridge itself, the team finalised the barrier stitch pours and installed elliptical top-rails, culminating in the laying of a leveling layer of asphalt on the bridge deck.

Looking ahead, the team's focus includes chip sealing and laying the final asphalt layer across both approaches and the bridge deck, a task contingent on favorable weather conditions. Additional tasks involve the installation of side barriers on the approach roads, ongoing stormwater drainage efforts, and completion of finishing works encompassing line marking and signage installations.

Special Delivery from Tairua School

A heartwarming gesture arrived at our Hamilton office last week—a meticulously crafted card from the students at Tairua School. Accompanied by a letter penned by the acting school principal, Sandy Blackburn, expressing heartfelt gratitude for the early reopening of the road.

Described as "a lifeline for local businesses and our school community," the appreciation from Tairua School has deeply touched both our project team and contractors. The entire SH25A team extends heartfelt thanks to the Tairua School community for their thoughtful gesture.

Meet the Team - Project Administrator Michelle Pluim

Project administrator Michelle Pluim, affiliated with McConnell Dowell, is a Thames resident with an extensive background in accounting and administration roles spanning over 20 years.

When asked about the significance of this project, Michelle highlighted her personal connection to the area and its community. Having witnessed the local impact of the storm-induced slip, she finds fulfillment in contributing to a project close to home.

Michelle's strong ties to Thames and surrounding areas, coupled with her family-oriented lifestyle, reflect her dedication to community engagement outside of work. Her weekends are often spent exploring local landscapes, beaches, and rivers, relishing moments with family and friends.

Roading update for 28 November 2023

Advancements in Bridge Construction

Last week marked significant progress in securing the side barriers onto the bridge deck as the team undertook the meticulous process of completing concrete 'stitch' pours. As of last Friday, 31 out of the 48 pours were successfully executed, with the remaining set to conclude this week. The installation of steel rails atop the barriers is scheduled for the upcoming week.

On the eastern approach, the groundwork for the new pavement's basecourse layer was stabilised, and efforts were focused on the installation of stormwater u-channels. Simultaneously, at the western approach, the team achieved the installation of the bridge's expansion joint, completed the knock-off block pour, and commenced the road reinstatement process to link with the new bridge.

Additionally, measures have been initiated to stabilise the top steep section of the slip face by installing mesh, while ongoing drainage works below the bridge continue.

Meet the Team - Project Engineer Alison Craigie

Alison Craigie, serving as the project engineer for the bridge's 'superstructure' involving the deck and piers, is a member of Fulton Hogan.

Work History and Insights

With a construction background spanning nearly 12 years, Alison initially ventured into construction during her tenure as a summer student at the Victoria Park Tunnel in 2011/2012. Her experience includes involvement in several significant bridge projects across Auckland, and most recently, contributing to the Project Pure Wastewater Treatment Plant Upgrade in Wanaka.

Project Significance and Community Impact

Alison finds this project particularly special due to its profound impact on the community. The restoration of this critical roading connection holds immense significance, and being part of the reconnection process is rewarding. The project's focused goal and remarkable progress have been outstanding. Previous projects have served as valuable learning experiences, offering insights to enhance operations based on past encounters.

Local Links and Interests

While previously unconnected to the area, Alison has now established new ties in Thames and remains engaged with friends at the Squash Club. She currently resides in Thames within the Kaueranga Valley during the project, having originally hailed from Auckland and later relocating to Wanaka.

Off-Duty Pursuits

Outside work commitments, Alison frequents the squash club and enjoys the scenic local swimming spots for a refreshing swim, blending leisure with her professional responsibilities.

Roading update for 20 November 2023

Bridge Progress Unveiled!

The SH25A bridge is reaching the final stages of construction, marked by the installation of precast concrete side barriers and crucial connections of the deck to the abutments.

During the past week, the team positioned 44 barriers on each side of the bridge deck, enhancing safety measures. Simultaneously, the eastern abutment saw the completion of concrete pouring for the expansion joint and knock-off block, pivotal components explained below.

The continuous soil nailing work above the bridge, including night shifts, is propelling progress. Under-bridge drainage installation and ongoing work at the western abutment also saw significant advancements.

Furthermore, the team finalised the pavement layers for the new road at the eastern approach, preparing for the final sealing with asphalt.

Looking ahead, the team is set to reinforce connections between barriers and the bridge deck, as well as commence the construction and pouring of the expansion joint and knock-off block at the western abutment. Road reinstatement work at the western approach will also kick off.

In the coming weeks, activities such as asphalt laying, road marking, and barrier installation will pave the way for the bridge's imminent opening.

Unraveling Technical Features

Understanding bridge intricacies: Knock-off blocks and expansion joints are integral design elements facilitating flexibility and resilience in concrete bridges.

Knock-off blocks act as deliberate weak points in the bridge's design, serving an earthquake-resistant purpose. In the event of seismic movement, these blocks absorb impact, protecting the abutment and overall structure from damage.

Expansion joints alleviate stress caused by factors like thermal expansion and contraction, offering flexibility within concrete deck bridges.

Community Appreciation

The overwhelming community response following the announcement of SH25A's early reopening has deeply touched the project team. Regional Manager Infrastructure Delivery, Jo Wilton, expressed gratitude for the outpouring of support, acknowledging the tireless efforts of both the project team and contractors in achieving this milestone. The heartening feedback has been a morale booster, affirming the recognition of their hard work.

Roading update for 13 November 2023

Pre-Christmas opening confirmed for SH25A

In preparation for the upcoming holidays, Waka Kotahi has confirmed that State Highway 25A (SH25A) between Kōpū and Hikuai will be reopened to traffic by December 20, 2023 – a significant three months earlier than initially anticipated. This timely reopening is a crucial effort to reconnect both sides of the Coromandel region, alleviating the impact on local families, businesses, schools, and communities caused by the highway closure.

Waka Kotahi, in collaboration with builders McConnell Dowell and Fulton Hogan JV, has executed an exceptional achievement in completing the 124-meter bridge in less than seven months. Typically, a bridge of this nature would require 18 to 24 months for design and construction. The expedited timeline was made possible by leveraging a similar bridge design from another project, allowing early material orders and commencement of work even before the SH25A design was finalised.

Despite this remarkable progress, there is still substantial work to be undertaken before the pre-Christmas opening. Upon the bridge's reopening, traffic management at a reduced speed will be implemented, followed by post-holiday finishing work, including drainage completion, earthworks, and the removal of temporary bracing under the bridge. This subsequent work will not necessitate road closure but may require intermittent traffic management.

The estimated cost of the bridge upon completion is approximately $43 million, falling under the initial $50 million estimate. Additionally, a supplementary investment of $25 million has been allocated to facilitate essential maintenance work, including slip clearance, culvert replacement, and road maintenance along the entire length of SH25A. This strategic investment aims to enhance the corridor's safety, resilience, and overall condition.

Weekly update

The recent update indicates substantial progress, with the installation of 138 deck panels, completion of drainage at the eastern approach, and ongoing soil nailing and mesh installation for slip face stabilsation. The upcoming week will see the installation of 52 concrete barriers, each weighing three tonnes, and progress in various critical tasks, such as soil nailing, concrete side barrier installation, asphalting, road surfacing, and line marking.

Watch the timelapse of the of deck panel installation here.

Roading update for 6 November 2023

Despite a challenging start to the week due to unfavorable weather, the SH25A Taparahi team pressed on with their mission. They continued installing precast deck panels, drilling soil nails for slip face stabilization, and completed earthworks at the bridge's eastern approach.

To date, a total of 70 precast panels have been securely positioned. The panels are meticulously interconnected with steel reinforcement and concrete, ensuring the structural integrity of the bridge. The dedicated steel fixers are already hard at work installing the reinforcement, and the first of three concrete pours is scheduled for early this week.

In a remarkable step forward, the first of two new drainage road crossings was finalised. Furthermore, one of the 100-ton cranes was demobilised as it's no longer needed for the project.

The upcoming week's plan, weather permitting, involves the continued installation of precast deck panels and preparations for deck stitch concrete pours.

The team has made significant strides with their soil nail drilling efforts on the slip face, working diligently with both day and night shifts. This construction technique, known as soil nailing, plays a pivotal role in fortifying unstable soil slopes. It involves drilling angled holes into the slope, inserting reinforcing bars, and grouting them into place. This process effectively unifies the soil into a sturdy block and is usually reinforced with a flexible mesh to secure shallow soils between the nails.

Meet the Team: Structures Foreman Andrew Pluim

Structures Foreman Andrew Pluim, who works for McConnell Dowell, is enjoying his role on the SH25A project, especially since he's a Thames resident and doesn't have to travel far for work.

• Any Local Links?

Andrew resides in Thames, making this project an exceptional opportunity for him to contribute to his local community. The convenience of working close to home and being near his family is greatly appreciated.

• Tell us a Little About Your Work History

With over two decades of experience in the construction industry, Andrew has worked across various sectors. Some of his notable projects include the City Rail Link in Auckland, oil and gas projects in Western Australia, and the Old Māngere Bridge Replacement project – Ngā Hāu Māngere Bridge.

• What's Special About This Project?

This project holds special significance due to its vital importance to the local community. The fast-paced nature of the work and the challenging environment make it a unique endeavor. Andrew's previous experience with Waka Kotahi projects has equipped him with valuable insights into what's expected: effective communication, high-quality work, and a safe and healthy work environment.

• What Might Locals Spot You Doing Outside of Work?

When not at work, Andrew enjoys spending time with his family, particularly exploring the walking trails and swimming in the Kauaeranga Valley during warmer months. He looks forward to returning to the surf spots on the east coast once SH25A is reopened.

Roading update for 30 October 2023 - Deck Panels in Place

As the skies threatened a wet and windy turn on the Coromandel Peninsula, the SH25A rebuild team managed to make significant progress over the weekend. They successfully lifted and installed 14 deck panels onto the bridge, giving a tangible glimpse of the bridge's upcoming structure.

While the adverse weather conditions did pause crane operations, the team's dedication allowed them to secure these vital deck panels in place. The deck is a fundamental component of the bridge, and this accomplishment signifies a significant step in the reconstruction process.

The concrete pre-cast deck panels and pre-cast barriers are steadily making their way to the site, with three-quarters of the panels and 16 barriers already on location. The remaining panels and barriers are in the fabrication process off-site.

Additionally, the team completed bracing and pier connection work on the bridge girders, ensuring the structural integrity of the bridge. Abutment bearings, which play a crucial role in transferring loads and allowing for temperature-induced expansion and contraction of the girders, were also installed.

On the ground, the team poured settlement slabs at both abutments. These slabs are designed to extend from the abutments, smoothing out any road approach settlement and providing a seamless experience as you cross onto the bridge.

Soil nailing work continues along the slip face, with the team using innovative techniques, including a man-cage suspended from a drilling rig to reach higher areas.

Furthermore, earthworks at the eastern approach to the bridge are nearly complete, enabling the installation of new culverts and side drains this week. The progress keeps the SH25A rebuild on track, pushing forward despite the weather challenges.

A Tale of Two Bridges: A Lesson in Collaboration and Prioritisation

In the world of infrastructure projects, adaptation and collaboration sometimes lead to remarkable outcomes. The State Highway 25A (SH25A) bridge rebuild in the Coromandel Peninsula is a prime example of this.

The challenge was clear: construct a 124-meter, 3-span bridge with the expectation of reopening the road to traffic by March 2024. To meet this goal, a dynamic approach was necessary.

A unique solution emerged. Steel plates originally intended for the Minden bridge on Tauranga’s Takitimu North Link project found a new purpose – the SH25A bridge build in the Coromandel. These plates were originally scheduled for installation next year but were repurposed for the SH25A bridge, and replacements for the Minden site were arranged in time to meet their revised program.

This shift was possible because the two bridge projects shared significant similarities in their steel beam profiles, making the transition feasible without extensive modifications. It's a shining example of collaboration and prioritisation, demonstrating how vital infrastructure can be delivered promptly to communities in need.

This thoughtful decision has significantly contributed to the expedited progress of the SH25A bridge project. Watch how the steel plates are being repurposed for the SH25A bridge here.

Roading update for 24 October 2023 - Taking Shape!

Exciting developments at the SH25A Taparahi Bridge project as the final girder (beam) was lifted into place on Wednesday, October 18th, just 10 days after the installation of the first one. These steel girders, which are a vital component of the bridge structure, consist of 15 sections bolted together to create a solid foundation. They will ultimately support over 1000 tonnes of concrete, asphalt, and precast side barriers, all part of the bridge's deck surface.

In total, the girders will carry a weight of 1560 tonnes before the first vehicle drives across the bridge. To ensure a smooth ride, the girders are designed with a slight arch profile to prevent any roller coaster effect. The entire process, from design to fabrication, is closely monitored to ensure precision.

Alongside this achievement, the abutments are now complete, with concrete pouring for the wing walls. Additionally, slip stabilization work is ongoing, with soil nailing in progress on the eastern slip. Earthworks have also begun on the eastern approach, including flattening the banks and creating space for drainage channels and side barriers.

Meet the Team: Site Engineer Nikhila Leelaratna

Meet Nikhila Leelaratna, a 22-year-old site engineer from Auckland who is now residing in Thames for the duration of the SH25A Taparahi Bridge project.

In his role, Nikhila has taken on various responsibilities in this fast-paced project. These include coordinating the stabilisation of the slip face to prevent future landslides and participating in the construction of pier columns, which support the bridge deck.

While this project is a unique experience for Nikhila, it's one he values greatly. The support from the local community has been exceptional, making this undertaking a memorable one. Nikhila reflects on the importance of the behind-the-scenes work, often unseen but crucial for the project's progress. He notes the late-night emails and continuous planning that are essential aspects of this journey.

Laughter also plays a role in keeping the team's spirits high, with weekly team dinners and spontaneous quiz nights adding a touch of humor to the project. Nikhila looks forward to the day when he can drive by the completed bridge and proudly say, "I helped build this."

16 October

The initial phase of bridge deck construction is officially underway at the SH25A Taparahi Bridge project. During the past week and over the weekend, the team successfully installed three spans of girders. These girders, long steel beams, play a vital role in spanning the distance between the abutments and piers, providing essential support for the bridge deck.

The girders are assembled in combinations of 18-metre and 29-metre sections and are then lifted into their designated positions. As work progresses, steel bracing is also gradually installed between the steel girders. The team is diligently advancing from Abutment A (the western abutment) to Abutment D (the eastern abutment).

This week, the primary focus is on preparing the girders for the final span, extending from Pier C to Abutment D. However, the success of these lifts is highly dependent on weather conditions, with strong winds necessitating safety precautions and possible delays.

Additionally, here's a recap of other activities conducted both on and off-site during the previous week:

Abutment A: The wingwalls have been finalised and are set for pouring this week.

Abutment D: Steel reinforcement for the wingwalls has been secured and is now ready for the concrete pour this week.

Pier B and C: Plinths have been poured, and the third span was successfully lifted into position over the weekend.

Offsite: The final three steel girders are scheduled to depart from Napier and are expected to arrive on-site this week. In the meantime, fabrication efforts continue for the 138 concrete pre-cast panels (which will form the bridge deck atop the steel beams) and 52 pre-cast side barriers.

The project continues to make significant strides towards completion, with teamwork and dedication driving every step of the process.

Roading update for 9 October 2023 - Arrival of First Bridge Beams

Last week, the project team welcomed a significant delivery on-site - the first two sets of bridge steel beams (girders). These beams vary in length, ranging from 18 to 30 meters, and weigh approximately 20 tonnes each. On-site, they will be joined together to form the foundation of the bridge deck, specifically for the first span of this 3-span bridge.

Ongoing activities include soil nailing and mesh installation, essential for stabilizing the slip face and containing potential debris from falling (refer to the left image below).

Here's a summary of other notable accomplishments from last week:

Abutment A: The team is actively securing steel reinforcement for the wingwall, with a concrete pour scheduled for this week (refer to the right image below).

Abutment D: The first section of the headwall and plinths was successfully poured last week. The next step involves tying the steel reinforcement for the wingwalls.

Pier B: This pier is fully completed and prepared for the installation of the bridge beams (girders).

Pier C: The headstock was completed, and plinths are set for pouring this week. This signifies the readiness of Pier C for the upcoming bridge beam installation.

Offsite: Out of the total 15 bridge beams, 12 have been delivered to the site, with the final 3 expected to arrive next week. Meanwhile, fabrication continues for concrete pre-cast panels and pre-cast barriers.

For an exciting visual of the bridge construction progress, check out the timelapse video captured between September 23 and October 3, showcasing the installation of the bridge's support columns. You'll find this at the bottom of this article.

Roading update for 4 October 2023

Progress at the Taparahi bridge site is steadily advancing, revealing the emergence of a bridge structure. The piers and abutments are taking shape, offering a glimpse of the future appearance of the bridge.

The bridge consists of four crucial structural elements: two piers and two abutments. The second pier, Pier C, was successfully completed last week, and the team's current focus is on finishing Pier B by the end of this week.

The next pivotal stage involves the delivery of the bridge beams, composed of steel girders. A total of 15 bridge beams are being manufactured offsite in Napier. The first two sets are expected to arrive at the site this week, and if weather conditions permit, the team hopes to witness the placement of the initial set of bridge beams next week. Wind conditions play a vital role in determining the timing of this operation.

Pictured above: the columns for piers B and C.

These bridge beams will be positioned atop the piers and abutments, forming the foundation for the bridge deck.

Abutment A: The headwall was poured during the previous week, and work on the wingwalls is set to commence this week. Headwalls offer essential support for bridges, while wingwalls provide support and safeguard the abutment.

Abutment D: The primary abutment beam has been poured, and the team aims to complete the headwall construction this week.

Pier B: The headstock and plinth have been fixed, formed, and concreted in preparation for the installation of the steel girders. Headstocks serve to support the bridge spans and transfer the bridge load to the underlying pier.

Pier C: The four columns constituting the pier have been filled with concrete, and the working platform has been lifted and placed on top as depicted in the images. Headstock construction is scheduled to commence this week.

Additionally, the project team will continue their efforts to install soil nails, which will stabilise the slope and fan drains.

Roading update for 25 September 2023

Impressive strides have been made in the construction of the bridge, as evidenced by the latest timelapse footage showcasing the substantial progress achieved.

In the realm of construction, unpredictability is a constant, and at this stage, uncertainties persist in the program. These uncertainties encompass aspects such as the fabrication of beams, deck construction, and the potential impacts of wind on crane operations. To tackle these challenges, close collaboration with the contractor remains a top priority as they work diligently to expedite project delivery. Currently, the contractor is adhering to the proposed program, and Waka Kotahi confirm the successful completion of the piling phase, thanks to the exceptional crew.

Acknowledging the pivotal role this road plays in the Coromandel region, the team is fully committed to completing the bridge within the shortest possible timeframe.

Since the last update, significant milestones have been achieved:

- The bridge piling phase has been successfully concluded, and the dedicated crew and rig have moved on to their next project.

- Notably, earthworks and slip stabilisation are nearing completion, a remarkable feat given the challenging conditions encountered during the initial two months of the project.

- Above-ground bridge construction is making remarkable progress.

- At Abutment A + D, the first two pours have been completed, including the main beam and the plinth. Steel fixing for the main beam at Abutment D has also been accomplished.

- Moving to Pier B, the installation of steel casing and reinforcement for the final two columns has been completed, with all four columns now poured. These columns constitute the foundation for the bridge deck. The photos showcase a specially constructed platform at the site, which was later lifted atop the columns to facilitate safe access during pouring and headstock assembly.

- Pier C has witnessed the drilling and pouring of all four piles, marking the final set for the new bridge. These piles have been cropped, and preparations are underway to position steel columns and temporary structures for an upcoming concrete pour.

- Offsite activities are progressing smoothly. The first set of steel bridge girders has been coated and is poised to depart from Napier. These girders, scheduled to arrive on-site in early October, will be strategically positioned between Abutment A and Pier B, forming the base of the bridge deck.

Pier B – installing final steel casing and cages, lifting the working platform in place, followed by the column pour.

Last week, the on-site team convened to celebrate the successful completion of the bridge piling phase and bid farewell to the piling crew and rig.

In Napier, the dedicated team continues to work tirelessly, with the first set of steel bridge girders prepared for their journey to Taparahi.

Roading update for 18 September 2023

In this last week, significant developments are evident, and there's exciting news to share - the commencement of work above ground, with the first two structures now visible at Pier B.

Abutment A and D: Blinding concrete has been successfully poured at Abutment D, marking a crucial milestone. Both Abutment A and Abutment D reinforcement cages have been skillfully positioned. The team is currently engaged in the intricate work of fixing and forming these cages in preparation for the inaugural abutment pour, slated for later this week.

Pier B: Notable achievements have been recorded at Pier B. Concrete pile pours have been completed, including a remarkable feat - the pouring of the deepest pile to date, reaching an impressive 41 meters. This depth is double that of the other piles, which extend to about 22 meters. These piles have already undergone cropping and rigorous integrity testing. Additionally, the team has initiated the installation of the column cages for the bridge. Remarkably, two out of four have already found their place at Pier B. As a result, the structure is beginning to emerge from the slip floor, marking a significant visual milestone.

Pier C: The working platform at Pier C has been successfully completed, and the piling rig has been strategically positioned. Four piles have been diligently drilled, with the first one receiving a pour September 18. This marks a pivotal moment in the Taparahi bridge piling activity, as the completion of these pours signals the demobilization of the piling rig and crew, who will soon embark on another project. Sincere thanks to the team for their dedicated efforts.

Off-site: Progress continues off-site as well. The steel bridge girders are steadily progressing through the paint booth in preparation for their upcoming transportation to the site later this month. Production is also underway for the precast concrete elements and the rails that will run along the top of the bridge barriers.

First Above-Ground Bridge Structures: An exciting moment has arrived as two out of the four column cages have been successfully installed at Pier B. This signifies the initiation of the actual bridge structure construction, a significant step forward for the project team on-site.

Roading update for 11 September 2023

Despite less-than-ideal weather conditions last week, the project team persevered and managed to stay on schedule. Work both offsite and at the Kōpū yard is ongoing, and there's an exciting transition occurring on-site. The team is shifting its focus from civil and ground-level work to the more visible and impactful bridge and structural work, where the project truly takes shape.

Despite the rain, take a look at the progress achieved, starting from the Thames side (west) to the Hikuai side (east).

Abutment A: Essential preparation work, along with the completion of blinding, marked significant milestones. Blinding involves the application of a thin layer of concrete, creating a clean and dry working platform and serving as the foundation for the abutment beam. The team is now gearing up for above-ground work, involving the construction of the abutment beam and the wingwall, both composed of concrete. The wingwall will retain the ground as it transitions from the road to the bridge, while the abutment beam will serve as the base to which the bridge deck will be attached.

Pier B: The team has successfully installed four pile casings and poured three of them. The fourth is scheduled for pouring this week.

Pier C: At Pier C, the team has completed the soil nailing process and the working platform, setting the stage for the drilling rig to commence work on the final set of piles for the new bridge this week.

Abutment D: Similar to Abutment A, preparations are underway for blinding, with the team gearing up for above-ground work. This phase includes the construction of the abutment beam and wingwall, echoing the process on the Thames side. These elements are crucial for the bridge's overall structure.

Construction Team Engages with the Community

Last week, members of the SH25A bridge joint venture team participated in the Coromandel Area School's careers roadshow. Aimee Pene (Construction Manager), Ashley Cooper (Contract Manager), Leila Finau (Human Resources Coordinator), and Donna (Social and Broader Outcomes Advisor) shared their personal career journeys and work experiences with the attendees. Their goal was to introduce the youth to the construction industry, discussing the various projects undertaken by both companies, as well as the diverse roles available within the industry. The event enjoyed a strong turnout, with students from local schools and the wider community in attendance. It was an excellent opportunity to inspire and inform the younger generation about career prospects in construction.

Roading update for 4 September 2023

The past week witnessed significant activity at the SH25A Taparahi bridge worksite, with ongoing bridge piling efforts taking center stage. Here's a detailed update, enriched with technical specifics for those with an appetite for the finer details:

Abutment A: The piles at this location have been successfully completed and cropped down to the required specifications.

Pier B: The completion of the working platform (as depicted in the right image below) marks a crucial milestone. This achievement enables the mobilisation of the piling rig and a hefty 100-tonne crane into the slip area. Presently, the team is actively installing four 950mm diameter pile casings into the founding rock, with plans to pour them this week.

Pier C: Exceptional progress has been made in the installation of soil nails (illustrated in the left image below). The construction of the working platform is well underway. Once this phase is concluded, preparations will be in place for the relocation of the piling rig from Pier B to Pier C, facilitating the commencement of piling activities.

Abutment D: On the Hikuai side of the bridge, the team is diligently preparing for pile work. The arrival of the first abutment reinforcement on-site signals the initiation of above-ground work for abutment construction. This week, the team's focus has been on the reinforcement preparation for the initial pour of the in-situ concrete works.

Offsite: In an offsite context, significant developments have occurred. The first batch of steel girders has successfully completed fabrication and has transitioned to the protective coating booth. This marks the final phase in the offsite process for these initial girders before their transportation from Napier to the site.

Kōpū Yard: Activity at the Kōpū yard remains robust. The team continues their dedicated work in fabricating temporary components for the headstocks and columns, including forms and falsework.

Roading update for 25 August 2023

The project team is pulling out all the stops at the SH25A Taparahi site, benefiting from clear weather conditions. This week's productivity is evident, and here's a comprehensive update on the site preparations for the upcoming bridge construction. For those who relish the details, there's a fair share of technical information to delve into. Here's the latest report from the on-site team:

Abutment A: On the Thames side (west), the team successfully completed the installation of seismic casings, designed to envelop the upper four meters of the piles. Piling work is in progress, and the first pile received a concrete pour on Friday, August 25th.

The installation of fan drains has been successfully accomplished, significantly enhancing the drainage system on the slip site. The process of building up the working platform at Pier B for the piling rig and crane is ongoing. This involves layering and stabilizing the existing site materials. Next week, the piling rig will be set up in this location.

Pier C: The proof drilling phase is now wrapped up. This drilling aids in determining the required depth for the piers to reach the solid rock foundation. Furthermore, the team has commenced soil nailing, a process that will establish another secure working platform for the piling rig and crane once the piles are installed at Pier B.

Abutment D: A secured work zone has been created by excavating the slope and installing temporary soil nails. This enables the initiation of work on the abutment structure. The piles have undergone cropping and have successfully completed their integrity testing. The current focus involves grouting the external surfaces of the piles, in preparation for pouring the blinding concrete slab. This concrete layer provides a clean and solid foundation for the subsequent structural work.

Meanwhile, at the Kōpū yard, significant activity is taking place. Steel beams, critical for supporting the pier headstocks, are being fabricated. Additionally, formwork construction is in progress for both the abutment and headstock pours. The formwork serves as a mold for the concrete pours.

SH25A - Developments Beyond the Site

Beyond the site, important progress continues. Steel girders are actively being fabricated in Napier and are making commendable headway. The forthcoming week will witness the commencement of the application of a protective coating to the initial batch of girders. For those interested in a visual insight, a captivating video from EastBridge, the team responsible for this work, is available for viewing at the bottom of this article.

Roading update for 22 August 2023

Last Friday, a series of site visits were organized by Waka Kotahi at the SH25A Taparahi bridge worksite. Approximately 60 members from the Coromandel community and local businesses had the opportunity to witness the ongoing progress at the site firsthand.

Jo Wilton, Regional Manager Infrastructure Delivery, expressed the understanding of the challenges that the SH25A closure posed to the Coromandel communities, local businesses, and the urgency to reopen the road swiftly.

Given the remote location of the worksite, only a few community members had seen it, which prompted the arrangement of these site visits. The objective was to offer individuals a chance to grasp the scope of the project and the momentum of the work being carried out.

The response from attendees was positive, as they appreciated the opportunity to observe the active worksite, engage with the engineers, and gain insights into their methodologies and challenges while constructing the bridge.

Acknowledgment was extended to all participants for their presence, understanding that for some, it required a considerable journey.

The first group of visitors, including Deputy Prime Minister Hon Carmel Sepuloni, Minister of Transport Hon David Parker, Thames Coromandel Mayor Len Salt, Ngāti Maru representatives Wati Ngamane and Kelly Ngamane-Hudson, and Coromandel MP Scott Simpson, alongside local and national media, had the privilege of visiting the site. Subsequent groups also visited the Taparahi location to witness the ongoing progress.

Project Progress

The piling process for the bridge's eastern abutment has been successfully completed. Currently, the contractors are engaged in drilling piles for the western abutment.

Additionally, the construction of the shear key, a substantial wall that reaches five meters into the slip to stabilise the slip floor and create a secure platform for equipment used in building the new bridge, has been finalized.

Efforts to enhance slip face stability and drainage are also in progress. A drainage system, extending 20 meters horizontally into the slip face, is being installed.

Challenges and Relocation

Just like the visitors and residents experience, the project team also encountered challenges in relocating the piling rig. Despite the relatively short distance of approximately 125 meters between the two bridge abutments, the rig's relocation to the Kōpū side took two days.

The 100-tonne rig had to be disassembled for transport, making three separate trips to comply with weight restrictions on SH25. Additionally, two more loads of tools and equipment were transported. After traveling via Waihī, the rig was reassembled on the Thames side of the worksite.

Roading update for 11 August 2023

The past week's stable weather conditions have meant that the installation of seismic casings by the contractors at the eastern abutment of the new 124-metre bridge. These sizable steel pipes encase the three near-surface piles and allow for their movement during earthquakes.

Following this accomplishment, the subsequent tasks involve the placement of deep pile casings and reinforcing cages, paving the way for the initiation of concrete pile pouring during the ongoing week.

Significant progress has been made in constructing robust tracks with high load-bearing capacity, crucial for facilitating the transportation of heavy equipment required for building the bridge piers and raising the beams.

The drier weather has also played a pivotal role in advancing efforts to stabilise and drain the slip-face. A specialised crew and equipment are now on-site and have embarked on the installation of 250 soil nails, which will be driven into the slip face to enhance its stability.

Waka Kotahi are committed that efficient bridge construction doesn't compromise sustainability considerations.

Prioritising local material sourcing whenever feasible has enabled quicker material acquisition, minimising transportation emissions and associated costs. The seismic casings, the initial permanent components for the bridge, were procured from a contractor who had surplus steel in storage. Opting for transportation from Christchurch rather than importing steel from China not only expedited the process but also drastically reduced the transportation distance from around 11,000 kilometres to approximately 1,070 kilometres, leading to a substantial reduction in transport emissions.

The Waka Kotahi contractors have also established on-site offices, which have been outfitted with furniture from the charitable organisation known as All Heart. This initiative repurposes surplus office furniture, channelling it back into the market or communities. This circular approach is particularly beneficial for construction projects that frequently establish and dismantle site offices over a span of a few years.

Roading update for 4 August 2023

The SH25A site update on ground stabilising reports the team's progress amidst varying weather conditions. The recent week witnessed both favourable and challenging weather, with a mix of magical days and occasional downpours. The current week, however, boasts clear blue skies and cooler temperatures.

Weather plays a crucial role in ground stabilisation efforts. The teams are currently working on stabilising the ground, for which they require reasonably dry conditions to manage cement quantities and curing times effectively.

Presently, one team is injecting 75 tonnes of cement to a depth of five metres into approximately 300m3 (106 tonnes) of slip material at the base of the slip area. This procedure aims to retain and stabilise the ground in that area.

Another team is engaged in mixing 6,000m3 (equivalent to 2119 tonnes) of slip material with over 1,000 tonnes of lime and cement on the slope. This mixture will create a stable layer capable of supporting the heavy machinery operating in the area and, eventually, the new bridge. To facilitate the project, a local Kōpū yard has been designated to store machinery and materials. Additionally, the first six seismic pile casings have arrived on site and will soon be installed at the eastern abutment.

Machinery on site

The site is now bustling with heavy machinery. Last week, a 100-tonne support crane was delivered, preceding the arrival of the piling rig and casings. The piling rig, weighing 80 tonnes (82.2 tonnes to be exact), arrived in three truckloads. Upon setup, counterweights were attached, bringing the total weight to 100 tonnes.

Among the machinery present are seven excavators, boasting a combined earthmoving power of 124 tonnes. These include a 30-tonne, two 20-tonne, 14.5-tonne, 13-tonne, 10-tonne, 8.5-tonne, and 8-tonne excavators. Additionally, two 10-tonne tracked moxy's, also known as articulated dump trucks, and a 30-tonne tracked moxy are on-site. Several other machines, such as a broom sweeper, a roller, and some smaller drilling rigs, bring the total number of machines to 19.

First piles

The current week marks the commencement of the piling rig, with the 100-tonne rig driving the first piles for the new bridge. The initial focus is on installing the seismic casings, followed by the permanent piles. There will be eight 22-metre long permanent piles, organised in two sets of four, to support the new bridge deck. Each pile will be driven at least 10 metres into the rock to ensure a solid rock foundation, with some piles requiring a depth of at least 20 metres.

For the installation of piles, an auger or 'screw' method is being employed to minimise noise and vibration impacts on the ground and surrounding wildlife, promoting an environmentally friendly approach to the project.

Roading update for 1 August 2023

Three trucks have delivered a 100-tonne piling rig to the Taparahi slip site on SH25A. The rig mast, drill bits and body are now being assembled so the build can begin. The rig is being set up to begin construction and drill the piles for the eastern abutment of the bridge. The test drilling that determines the depth of the piles has already been completed.

The first step will be to wind in the seismic casings for the piles – the large tubular metal sleeve that provides unrestricted movement of the top portion of the pile under earthquake loading. These casings are being cut to length in New Zealand and progressively delivered to Kōpū, where they are being stored ready for use.

– Waka Kotahi NZTA

Other work happening on the site includes:

- Laying drainage above and below the bridge site

- Stabilising access tracks for machinery and rigs

Offsite, the bridge beams are underway and being prefabricated in Hawkes Bay. There are 15 beams being worked on around the clock in the Eastbridge factory in Napier.

Local engineers join the team on SH25A rebuild

Former Thames High School student Taylor Auld and James Davies from Pauanui have joined the SH25A project as site engineers.

I have family and friends impacted by the road closure so know just how important this project is for local businesses and communities.

– James Davies, Engineer SH25A Rebuild

Our roles are towards the bottom of the org-chart, but we are part of a highly experienced team focussed on building the bridge as quickly as possible.

– Taylor Auld, Lead Engineer SH25A Rebuild

Taylor has been working for Fulton Hogan in the South Island for the last three years after studying engineering in Christchurch.

James completed his engineering degree at Auckland University last year and started working with McConnell Dowell’s Graduate Programme in February.

Related Links

Bridge confirmed as solution to reopen Coromandel Peninsula SH25a State Highway • Temporary Speed Reductions announced for Coromandel's State Highway 25 • State Highway 25A to open by end of March 2024-

{{#owner}}

-

{{#url}}

{{#avatarSrc}}

{{name}} {{/url}} {{^url}} {{#avatar}} {{& avatar}} {{/avatar}} {{name}} {{/url}} - {{/owner}} {{#created}}

- {{created}} {{/created}}